Iso 2768-1; The tolerance of size is normally defined as the difference between the upper and lower dimensions.The need for tolerances to be identified on drawings is vital to allow assembly of parts in the desired way and interchangeability of parts as require in modern manufacturing methods.ISO 286 implements 20 grades of accuracy to satisfy the requirements of different industries.

- Tolerance class. Name for a combination of a fundamental deviation and a tolerance grade, e.g. Fundamental tolerance. A tolerance assigned to a fundamental tolerance grade, e.g. IT7 and a nominal dimension range, e.g. Planned joining condition between hole and shaft.

- Iso 2768 Hole Tolerance It6. Example for the DIN ISO 2768-2 tolerance table. This is just one example for linear tolerances for a 100mm value.

- Variations on dimensions without tolerance values are according to ' ISO 2768'. All tolerance limits are given in mm. ISO 2768 and derivative geometrical tolerance standards are intendedto simplify drawing specifications for mechanical tolerances. ISO 2768 is mainly for parts that are manufactured by way of machining or removal of materials.

According to DIN ISO 2768-1

According to DIN ISO 2768-2

General tolerances for linear measures and level squares with four tolerance classes are useful for simplifying drawings.

By choosing the tolerance class precision levels common in workshops should be taken into account.

If smaller tolerances are needed or bigger ones are more economical,

then these tolerances are indicated next to the nominal size.

Tabular 1 Limits for linear measures

| Tolerance- class | Limits in mm for nominal sizes in mm | |||||||

0,5 to 3 | above | above 6 to 30 | above 30 to 120 | above 120 to 400 | above 400 | above 1000 | above 2000 | |

| f (fine) | ± 0,05 | ± 0,05 | ± 0,1 | ± 0,15 | ± 0,2 | ± 0,3 | ± 0,5 | - |

| m (medium) | ± 0,1 | ± 0,1 | ± 0,2 | ± 0,3 | ± 0,5 | ± 0,8 | ± 1,2 | ± 2 |

| c (coarse) | ± 0,15 | ± 0,2 | ± 0,5 | ± 0,8 | ± 1,2 | ± 2 | ± 3 | ± 4 |

| v (very coarce grob) | - | ± 0,5 | ± 1 | ± 1,5 | ± 2,5 | ± 4 | ± 6 | ± 8 |

For nominal sizes below 0,5 mm the limit measures are to be indicated directly at the nominal measure.

Tabular 2 Limit measures for radius of curvature and chamfer height

| Tolerance class | Limits in mm for nominal sizes in mm | ||

0,5 to 3 | above 3 to 6 | above 6 | |

| f (finne) | ± 0,2 | ± 0,5 | ± 1 |

| m (medium) | |||

| c (coarse) | ± 0,4 | ± 1 | ± 2 |

| v (very coarse) | |||

Bei Nennmassen unter 0,5 mm sind die Grenzabmasse direkt am Nennmass anzugeben.

Tabelle 3 Grenzabmasse für Winkelmasse

| Tolerance class | Limits in mm for nominal sizes in mm | ||||

to 10 | above 10 to 50 | above 50 to 120 | above 50 to 400 | above 400 | |

| f (fine) | ± 1 ° | ± 30 ' | ± 20 ' | ± 10 ' | ± 5 ' |

| m (medium) | |||||

| c (coarse ) | ± 1 ° 30 ' | ± 1 ° | ± 30 ' | ± 15 ' | ± 10 ' |

| v (very coarce) | ± 3 ° | ± 2 ° | ± 1 ° | ± 30 ' | ± 20 ' |

For nominal sizes below 0,5 mm the limit measures are to be indicated directly at the nominal measure. If general tolerances according to ISO 2768-1 are valid,

the following has to be inserted in the title box, i.e. for tolerance class medium

ISO 2768 – m or general tolerance ISO 2768 – m

For new designs only the general tolerance according to DIN ISO 2768-1 should be valid. The limit measurements of the tolerance classes m and f of DIN ISO 2768-1 are identic with those of DIN 7168-1.

According to DIN ISO 2768-2

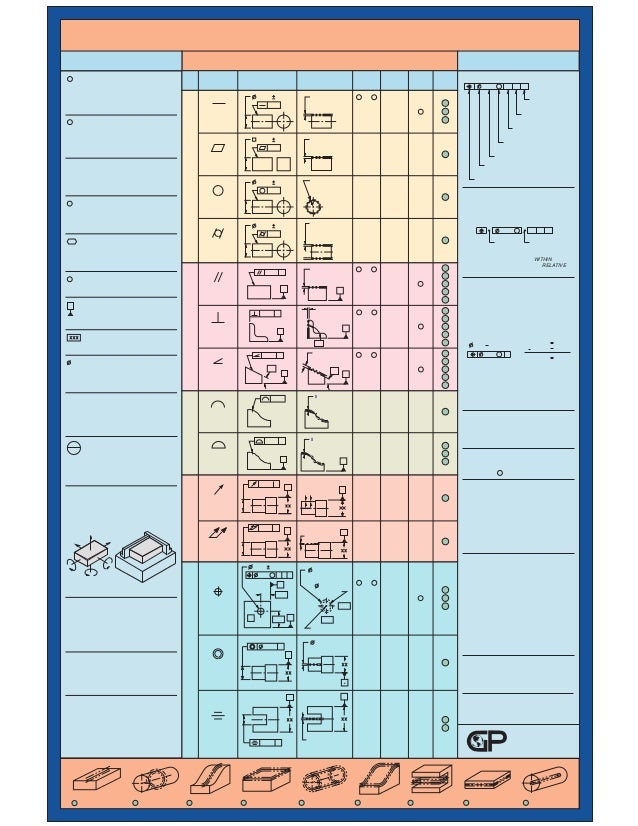

DIN ISO 2768-2 is for simplifying drawing and fixes general tolerances in three tolerance classes for form and position.

By choosing a special tolerance class exactly the precision level common in workshops should be taken into account.

If smaller tolerances are needed or bigger are more economical these tolerances should be mentioned directly according to ISO 1101.

General tolerances for form and position should be used while the tolerance principle according. to ISO 8015 is valid and while this is mentioned in the drawing.

This tolerance principles says that no opposite relation between measure, form and position tolerance exists (principle of superposition).

| Tolerance class | General tolerances for straightness and evenness in mm | |||||

Range of specified size in mm | ||||||

to 10 | above 10 to 30 | above 30 to 100 | above 100 to 300 | above 300 to 1000 | above 1000 to 3000 | |

H | 0,02 | 0,05 | 0,1 | 0,2 | 0,3 | 0,4 |

K | 0,05 | 0,1 | 0,2 | 0,4 | 0,6 | 0,8 |

L | 0,1 | 0,2 | 0,4 | 0,8 | 1,2 | 1,6 |

| Tolerance class | General tolerances for straightness and evenness in mm | |||||

Range of specified size in mm | ||||||

to 100 | above 100 to 300 | above 300 to 1000 | above 1000 to 3000 | |||

H | 0,2 | 0,3 | 0,4 | 0,5 | ||

K | 0,4 | 0,6 | 0,8 | 1 | ||

L | 0,6 | 1 | 1,5 | 2 | ||

| Tolerance class | General tolerances for symmetry | |||||

Range of specified size in mm | ||||||

to 100 | above 100 to 300 | above 300 to 1000 | above 1000 to 3000 | |||

H | 0,5 | |||||

K | 0,6 | 0,8 | 1 | |||

L | 0,6 | 1 | 1,5 | 2 | ||

General tolerances for form and position are valid for form elements for which form and position tolerances are not indicated individually.

They are applicable for all characteristics of the form elements accept cylinders, profiles of any line or surfaces, inclines, coaxiality, position and total movement.

Ramo AB ansvarar ej för eventuella felaktigheter i ovanstående information.

Din Iso 2768 Hole Tolerance

Ramo AB takes no responsibility in the eventuality of errors in the above information.

There is variability in any manufacturing process and, as such, tolerances are used to set permissible limits on this variability. Machining is often selected when tolerances are close, as it is more accurate than most other shape-making processes.

Tighter tolerances usually mean higher costs. For example, if the product designer specifies a tolerance of ±0.10 mm on a hole diameter of 6.0 mm, this tolerance could be achieved by a drilling operation. However, if the designer specifies a tolerance of ±0.025 mm, then an additional reaming operation is needed to satisfy this tighter requirement.

Iso 2768 Hole Tolerance It6

This is not to suggest that looser tolerances are always good. It often happens that closer tolerances and lower variability in the machining of the individual components will lead to fewer problems in assembly, final product testing, field service, and customer acceptance. Although these costs are not always as easy to quantify as direct manufacturing costs, they can nevertheless be significant. Tighter tolerances that push a factory to achieve better control over its manufacturing processes may lead to lower total operating costs for the company over the long run.

ISO 2768 is a standard for general tolerances, specifically covering linear dimensions, angular dimensions and geometrical tolerances. It is issued by the International Organisation for standardisation – ISO in association with Deutsches Institut für Normung – DIN.

The ISO 2768 standard comes in two parts, namely ISO 2768-1 and ISO 2768-2. The first part covers linear and angular dimensions, as well as radius of curvature and chamfer height according to four classes of levels: f (fine), m (medium), c (coarse), v (very coarse). The second parts covers geometrical tolerances in regard of form and position according to three classes or levels: H (fine), K (medium), L (coarse).

At CNC Proto we specialise in the machining of non-ferrous metals, mostly 6000 and 7000 series aluminium alloys, and engineering plastics. On our Quote Request form, we offer by default 3 different choices to our customers for linear and radii dimensions general tolerances (+/- 0.10mm; +/- 0.07mm; +/- 0.05mm). Of course, if you prefer to specify your general part tolerances according to ISO-2768, feel free to let us know in the additional comments field of the form!

For more articles on CNC machining, materials and design of machined parts, be sure to check our Resource Library.

With an MSc. in Mechanical Engineering, Fernando has worked 8 years at CERN designing and building the next generation of particle detectors alongside top European engineers and physicists. Being passionate about CNC machining, he started CNC Proto, an online CNC machining service in Europe dedicated to providing fast turnaround, high quality parts at a competitive cost. Learn more About Us.

Upload your design, specify quantity, material and finish to receive within the next 24 hours a free quote for your CNC parts