Tolerances of ISO 2768 cumulative or not?

Tolerances of ISO 2768 cumulative or not?

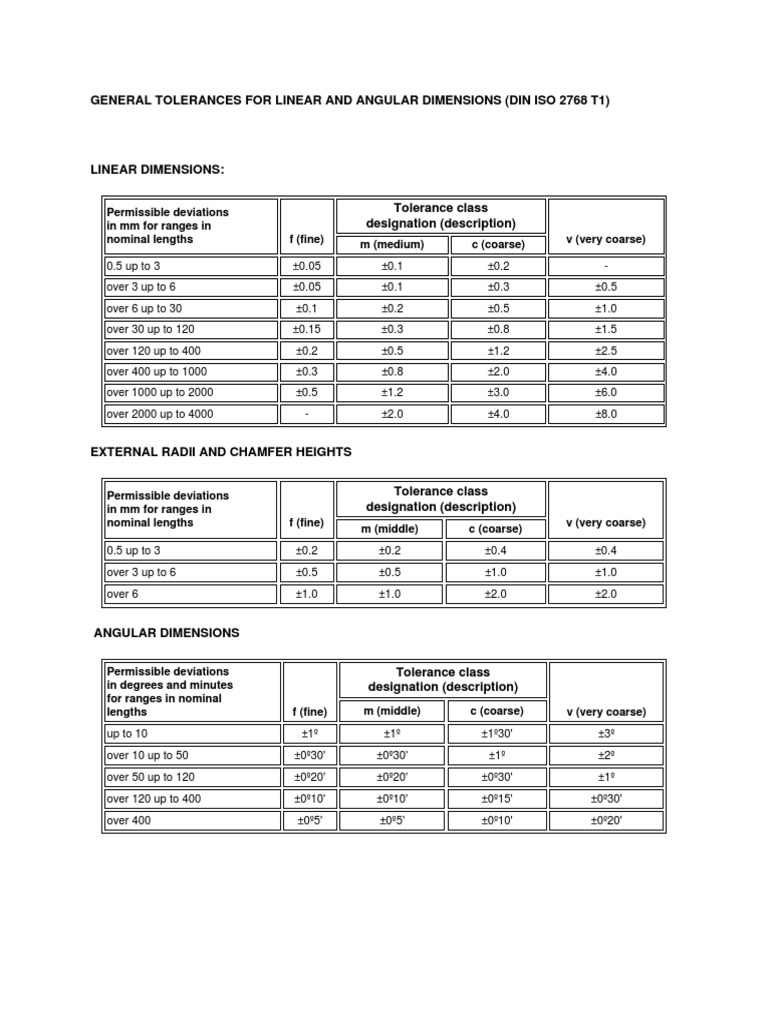

All tolerance limits are given in mm. ISO 2768 and derivative geometrical tolerance standards are intendedto simplify drawing specifications for mechanical tolerances. ISO 2768 is mainly for parts that are manufactured by way of machining or removal of materials. Table of typical hole fits. Part 1: General Tolerances ISO 2768-1. ISO 2768-1 is intended to simplify drawing indications and specifies general tolerances in 4 tolerance classes (f – fine, m – medium, c – coarse, v – very coarse). It applies for the linear dimensions and angular dimensions such as external sizes, internal sizes, step sizes, diameters, radii.

ISO 286 Table Hole Tolerances Calculator; International Tolerance Grades; Variations on dimensions without tolerance values are according to ' ISO 2768'. All tolerance limits are given in mm. ISO 2768 and derivative geometrical tolerance standards are intendedto simplify drawing specifications for mechanical tolerances. ISO 2768 is mainly for. Jun 26, 2019 Iso 2768 Mk Tolerances For Holes The better the deviation from focus on, the greater is certainly the reduction. This is definitely referred to as the or 'high quality loss functionality', and it is the key concept of an substitute system called 'inertial tolerancing'. 'ISO 2768 invokes a set of general tolerances based on a study of common machine shop practices. If the part does not meet these general tolerances, the part might still be accepted if it seems to work in its' function.

Ken had a thread awhile back on a discussion he had with a German engineer who clamed they were non-cumlative. I like Ken had always assumed they would be cumulative between the non-dimensioned features. Does anyone out there know? Can you reference why and where this is stated?

Thanks,

Frank

GD&T (GPS) per ISO 1101, 8015, & 2768

ISO-2768 Tolerance Chart - OEM Metal Parts

GD&T (GPS) per ISO 1101, 8015, & 2768

Iso 2768 Hole Tolerances

Working for a very global oriented company, we use ISO for all Global Dimensioning and Tolerancing standards for our drawings. After receiving training per the ASME Y14.5 standard, it has been a constant state of confusion for me while trying to understand our standard tolerancing schemes that we have on our prints.

Time and time again I have seen prints that outright conflict with ASME, and most often they lack very important controls, and sometimes datums, to insure proper function of the parts. Every time I question or comment about this, I am always told that our general tolerance callout of ISO 2768 covers anything not stated. Now I have never been trained per ISO and I have had a difficult time finding training, in the US, for the many documents that make up the ISO Geometrical Product Specifications (GPS).

Recently, there has been a push to provide further development to our Design Engineers and Technical Drawers in the area of making and understanding drawings made to the ISO standards. As a result, we have been watching internal training videos on the subject matter. This is where my

While I expected some slight differences, like ISO Concentricity is very similarly used as ASME Position, I was absolutely SHOCKED when I got to the short training video on the „General Tolerances' portion of ISO 8015 and 2768. I took some screen captures of the example shown by the video. So can any of the experts here tell me their $0.02 on this matter?

Has as anyone here actually been formally trained to the ISO standard? We are starting to really push towards sourcing parts to new suppliers in countries not accustomed to DIN/ISO, and I am not certain that we will all be speaking the same engineering „Language'.

-Ryan